Case Studies

Efficiencies in Plant Design

Efficiencies in Plant Design

Challenge:

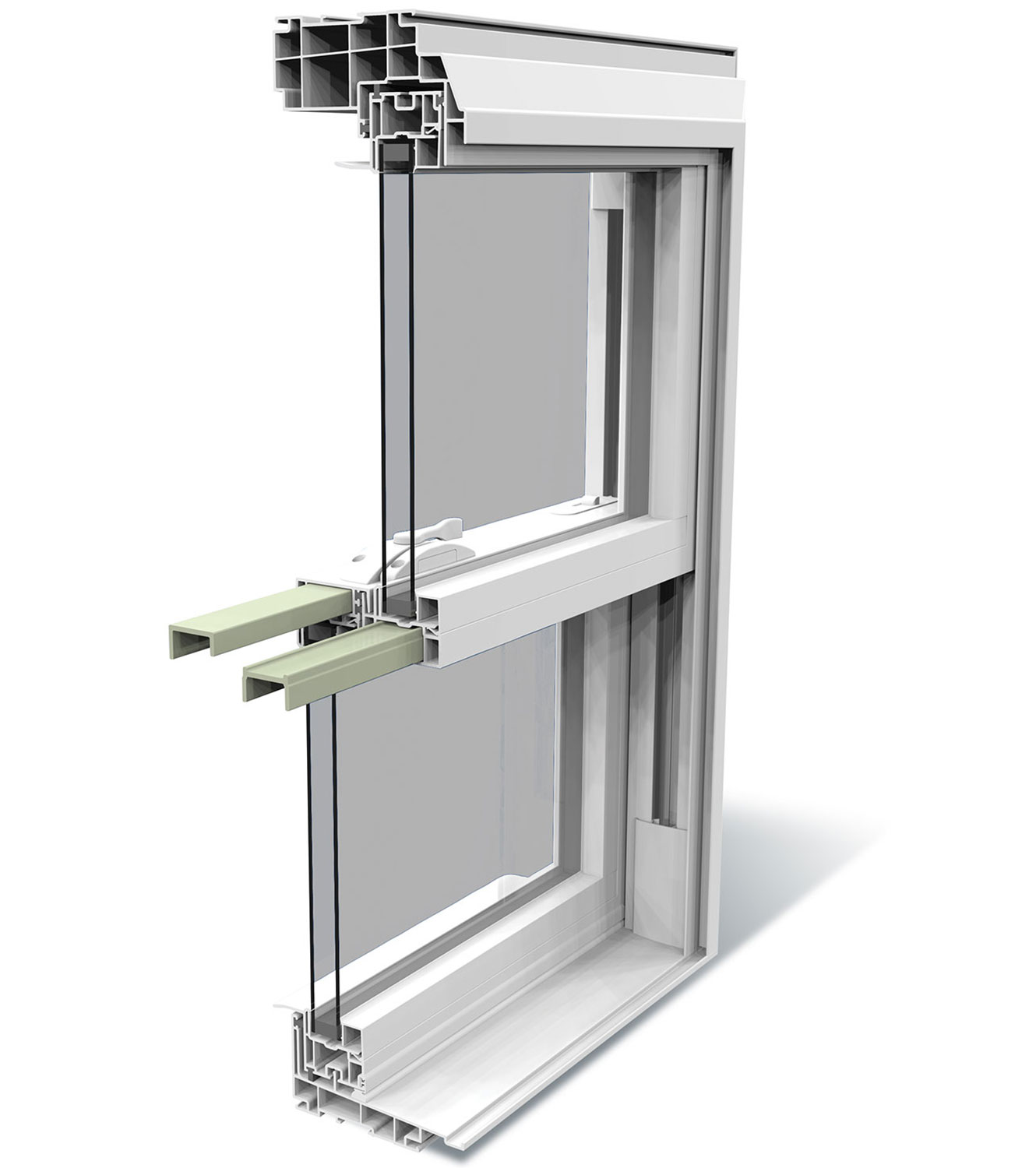

When window fabricators begin manufacturing a new product line, it can cost a significant amount of money to integrate the assembly line for efficient production. Fabricators need to increase capacities and efficiencies in their existing manufacturing facility to increase profitability and quality.

Solution:

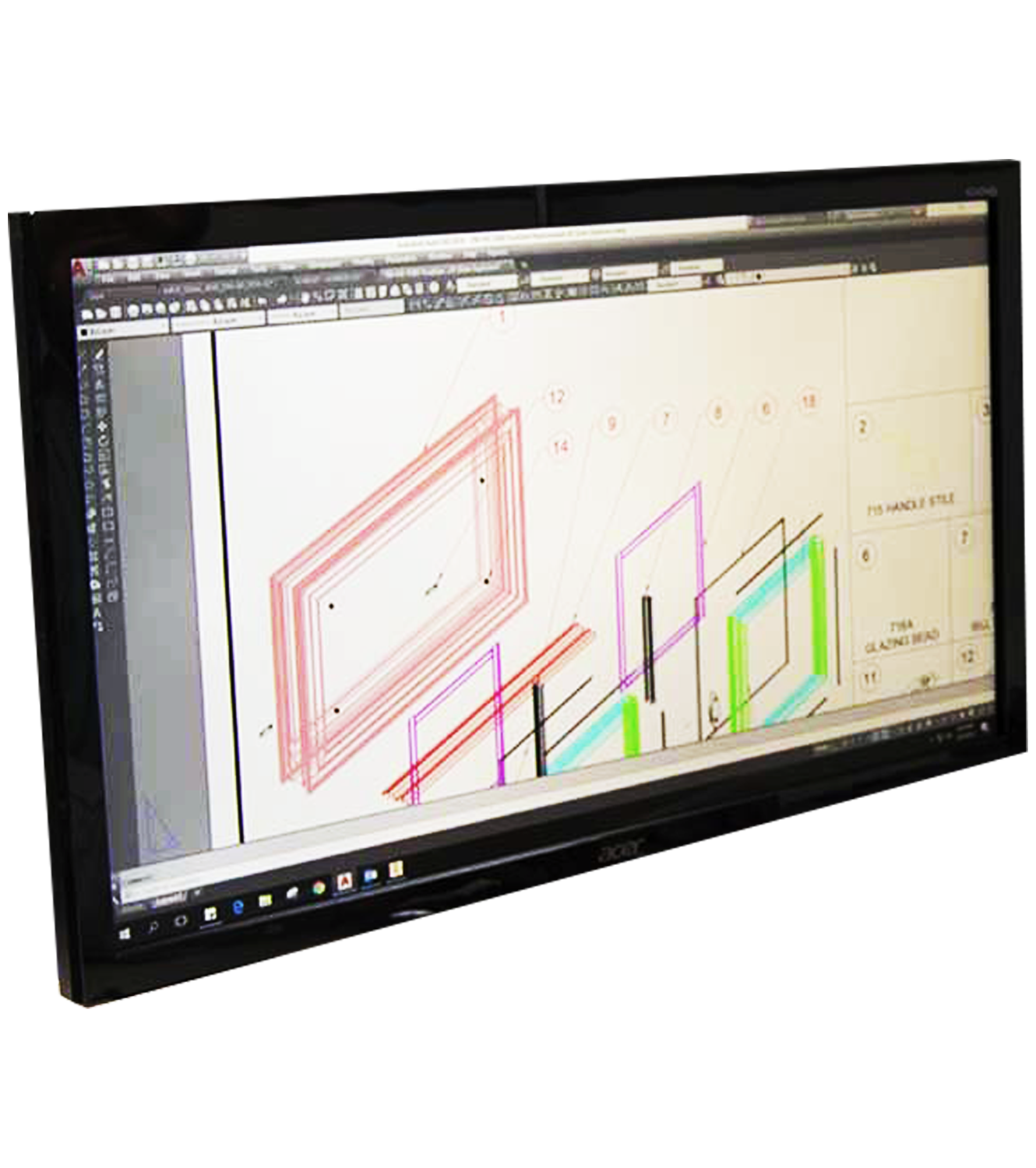

Chelsea Building Products’ Technical Service team studies the current manufacturing operation and then provides a blueprint of the systematic and functional arrangement of the various machines and equipment found throughout their entire window manufacturing plant. This provides a more efficient streamlined assembly line while reducing the cost of labor. The new customized plant layout is created to use all available resources in an organized multi-tiered manner to get the optimum efficiency and productivity out of the manufacturing facility.

- Increase labor efficiency

- Decrease labor costs

- Most efficient use of the available manufacturing floor footprint

- Continuous flow manufacturing, reducing WIP (work-in progress)